Encap Thermoplastics Ltd offers high-quality, reliable tooling services for a variety of applications and industries. As a small, family-run business, we offer a personalised service and significant savings compared to our larger competitors. Discover more about our Tooling Services and get in touch with our friendly expert team today.

Tooling Services

Fast, Friendly & Efficient

Our Tooling Services

For over 20 years, we have provided tooling services to a diverse variety of industries including industrial, electronics, medical, scientific, automotive and consumer goods. So, how can we help? Here are the tooling services you can take advantage of when you come to us…

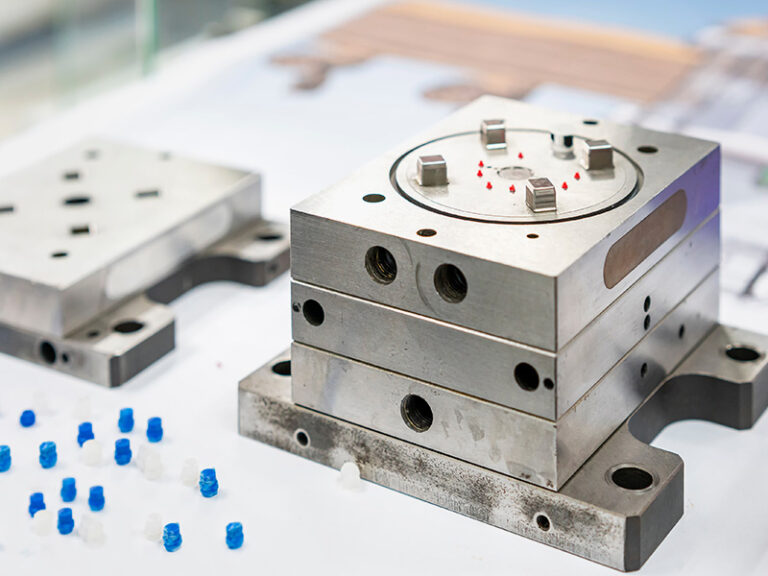

Plastic Injection Mould Tool Design

Using 3D CAD software we can design injection mould tooling for your existing part designs. With our extensive knowledge of the production process, we are well-placed to offer advice and suggest any changes required to reduce costs and improve the mouldability of your existing designs.

New Injection Mould Tooling

Encap has close links with local toolmakers and can source injection mould tooling plus any additional jigs and fixtures which may be required to assemble and finish your product.

You can be confident that tooling sourced by Encap will be maintained throughout it’s working life.

Existing Injection Mould Tooling

If you supply an existing mould tool, we will assess its suitablility for the expected life of the project and organise any modifcations or improvments as required.

How does it work?

We take care of your project every step of the way, from initial concept development and CAD design to prototype manufacture and full production. New injection mould tooling projects go through the following stages:

Initial Enquiry

We start by understanding your needs and gathering all the necessary details about your project.

Injection Mould CAD Design

We can design injection mould tools either from supplied CAD data or from product designs we create for you in-house.

Customer Approval

You’ll review and approve the CAD designs, ensuring they meet your specifications and expectations.

Tooling Manufacture

We work with local UK toolmakers to have your injection mould produced using high-quality materials for durability and precision.

T1 Sample Approval

You’ll receive T1 samples for final approval, allowing you to verify the quality and accuracy of the mould.

Full Production

Once approved, we move to full production, ensuring consistent and high-quality output for your project.

Ready to see how our tooling services can take your project from quotation to completion? All you need to do is contact us today.

The Benefits of Tooling Services with Encap Thermoplastics Ltd

1

Personalised Service

As a small, family-run business, we can provide a personalised touch to each project. You’ll receive the dedicated attention and bespoke solutions that larger, more corporate companies often overlook.

2

Cost Savings

Enjoy significant savings with our competitive pricing. We offer high-quality moulding services at a fraction of the cost of our larger competitors, ensuring you get the best value for your investment.

3

Versatile Applications

Our expertise spans a wide range of industries, including industrial, electronics, medical, scientific, automotive, and consumer goods. No matter your industry, we can meet your requirements.

4

20+ Years of experience

With over 20 years in the toolmaking and plastic injection moulding industry, we have the experience to take your project from concept to production.

FAQs About Our Tooling Services

What types of industries are your services suitable for?

We serve a diverse range of industries, including industrial, electronics, medical, scientific, automotive, and consumer goods.

Do you offer injection mould tool design services?

Yes, we provide custom injection mould tool design services using CAD software. Get in touch with us for more information.

What materials can you design injection tool moulding for?

We have experience designing tooling to suit a wide variety of materials, including PP, PE, POM, PA6, PA66, ABS, ASA, PC, PVDF, PPE, PPO, HIPS, and GPPS.

How do you ensure the quality of your tooling services?

We are accredited to ISO 9001:2015, the international standard that defines the requirements for a Quality Management System (QMS). We also offer free samples before the first production run of new tooling, and our process includes T1 sample approval to ensure quality and accuracy.

Why work with us?

ENGINEERING EXCELLENCE SINCE 1971

COMPETITIVELY & AFFORDABLY PRICED

SUSTAINBLE RECYCLING PROCESSES

Ready for bespoke, high-quality Tooling Services? Contact us today for more information!

Contact Us

Get In Touch

Phone:

Location :

Encap Thermoplastics Ltd

Unit 4 Bentalls Business Park

Bentalls, Pipps Hill, Basildon, Essex, SS14 3BN

United Kingdom